Railroad Brakeman: Stopping Trains, Averting Disaster

An installment in our Appalachian History and Culture series

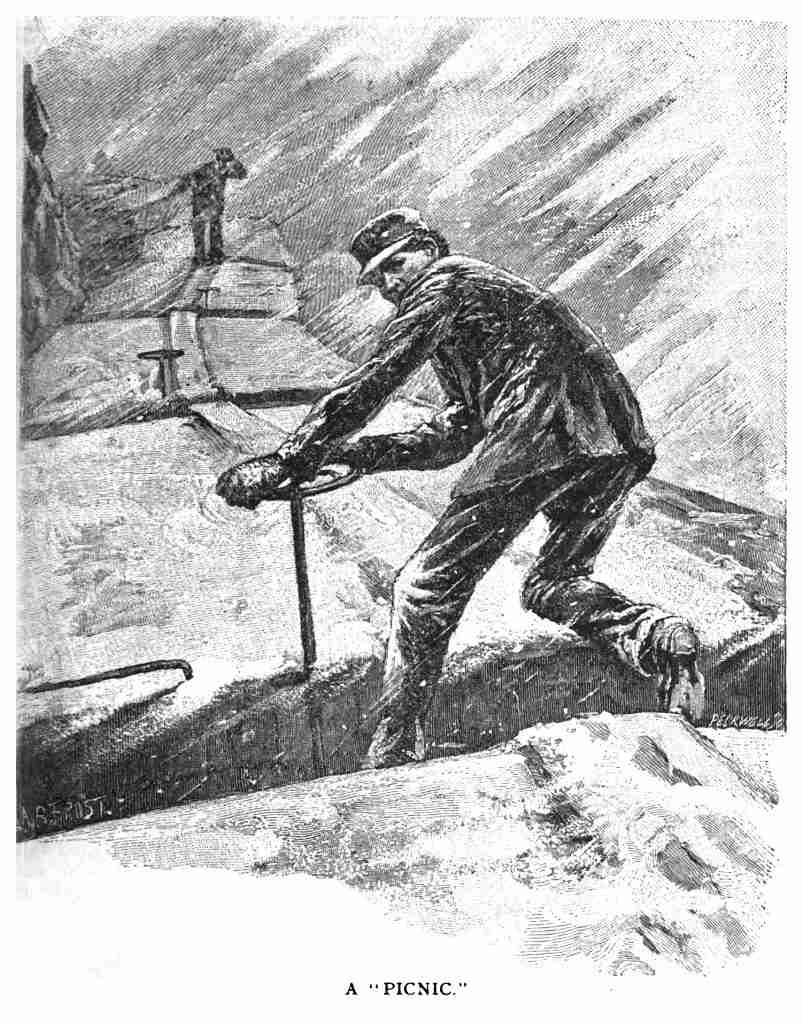

The wind tore through the brakeman’s jacket as he inched along the top of a freight car, his boots skidding slightly on the frosted steel. Below him, the Blue Ridge Mountains stretched out in waves, shrouded in a foggy mist. The train groaned and shuddered as it hugged a curve, and he gripped the brake wheel tighter, bracing himself against the motion. His lantern swung in his other hand, casting just enough light to illuminate the iron wheel he was about to turn.

This was his workplace—a moving train cutting through the Appalachian Mountains. To many, it might have seemed like madness to climb atop a moving train in the dead of winter, with the wind howling and the metal slick with ice. But for the brakeman, it was just another day on the job. He was responsible for ensuring the train slowed down when needed, whether descending a steep mountain grade or rolling into a station.

There was no room for mistakes. A loose coupling, a faulty brake—any of it could spell disaster for the men in the caboose or the cargo bound for some distant depot. He had seen what happened when things went wrong. He had lost friends to falls, crushed limbs, and runaway trains. But while he was up there, none of that mattered. He focused on the task, one brake wheel at a time.

The Early Days: Bravery and Grit on the Rails

A brakeman’s day began long before the train left the station. Before departure, he’d walk the train length, checking couplings to ensure each car was securely attached. This alone could be grueling, especially in freezing weather when metal fittings would stick or seize.

Once the train got moving, his real work began. To slow or stop the train, brakemen had to climb atop the cars, often while they were in motion, and manually crank the brake wheels on each car. On a good day, this meant battling strong winds and rattling metal. On a bad day, it meant icy surfaces, blinding snow, or searing heat. One misstep could send a man tumbling to the tracks below.

Brakemen also worked as a vital communication link between the engineer and the rest of the crew, using hand signals or lanterns to relay messages. They swung their lanterns in rhythmic arcs at night, guiding the train’s movements. These signals had to be precise—a single mistake could mean disaster.

Evolution Through Technology: The Air Brake Revolution

The job’s risks prompted innovation, and in the 1860s, George Westinghouse introduced the air brake. This system allowed engineers to simultaneously control all the train’s brakes from the locomotive. For brakemen, it was a game-changer.

At first, many brakemen resisted the new technology, fearing it would make their role obsolete. Some even sabotaged early air brake systems to prove their indispensability. But as the air brake’s reliability became clear, the role of the brakeman evolved. No longer needing to climb atop moving trains, brakemen shifted their focus to tasks like coupling cars, inspecting equipment, and ensuring safety.

Despite these changes, the job didn’t become easy overnight. Coupling and uncoupling cars was still hazardous, requiring the brakeman to step between rolling cars and align the heavy links and pins by hand. This task alone was responsible for countless injuries, earning rail work a reputation as one of the most dangerous industries.

The Modern Brakeman: Tradition Meets Technology

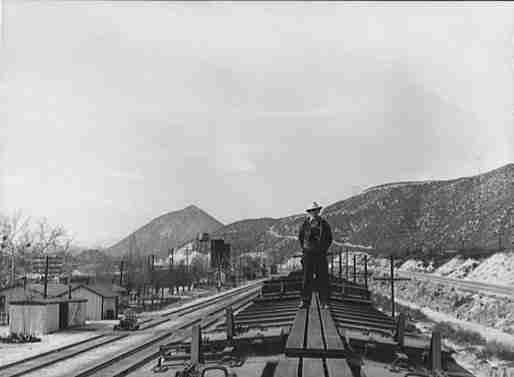

Today, the brakeman’s role is far from its perilous origins. Modern trains use sophisticated braking systems controlled electronically or hydraulically, eliminating the need for manual intervention. Brakemen, now often referred to as conductors, focus on inspections, troubleshooting, and communication with engineers.

Their duties include walking the length of the train to check couplings, inspecting mechanical components for signs of wear or failure, and ensuring cargo is secure. Modern trains are safer and more efficient, but the brakeman’s job still requires sharp instincts and attention to detail. A quick reaction can mean the difference between a minor issue and a major disaster.

The Legacy of the Brakeman

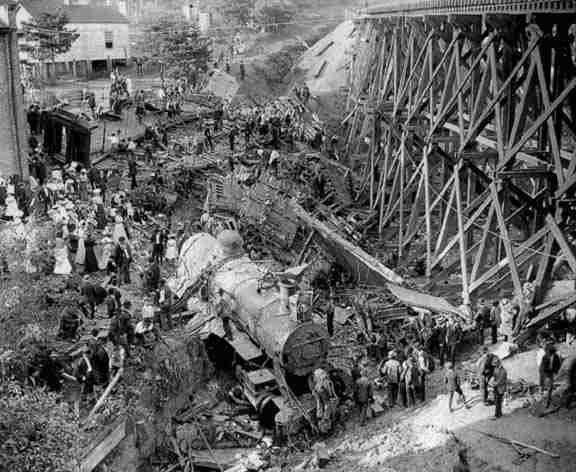

The brakeman’s story is woven into the fabric of American culture. Folk songs like “The Wreck of the Old 97” capture the drama and danger of the rails, immortalizing the bravery of railroad workers. Movies and Westerns often feature brakemen as unsung heroes battling against the odds to keep the train moving.

Beyond its cultural impact, the evolution of the brakeman’s role mirrors broader societal changes. It’s a story of progress—how technology improves safety and efficiency while altering how work is done. And though the tools and techniques have changed, the job’s core remains: ensuring the safe and reliable movement of goods and people.

Riding the Rails into the Future

The brakeman of today may not face the same dangers as his predecessors, but the role is no less vital. Whether inspecting equipment, coordinating with engineers, or troubleshooting issues on the fly, today’s brakemen carry on a tradition of resilience and adaptability.

So the next time you hear the distant whistle of a train or see one rumbling through your town, take a moment to think about the men who once risked everything atop those cars. Their legacy isn’t just a part of railroad history—it’s a testament to the courage and ingenuity that built America’s railroads. And it’s a reminder of just how far we’ve come.

More Appalachian History & Culture

Find more stories from the region’s past on the History and Culture page.

Appalachian History and Culture Collection

Enjoying Blue Ridge Tales? I hope so. If you’d like to help keep the site ad-free and the stories rolling, you can buy me a coffee.

To stay connected, subscribe to my Blue Ridge Tales newsletter, and have stories and updates delivered once a month to your inbox.